Custom Plastic Parts & Components

Quality Manufacturing Solutions Tailored to Your Needs

At SureSource, we specialize in the production of high-quality plastic parts, offering a broad range of solutions to meet the needs of industries that require both precision and cost-efficiency. Our expertise spans from small injection-molded components to large rotomolded products, ensuring that we can deliver custom solutions for projects of any scale. Whether you’re looking for extruded plastic sections, vacuum-formed parts, or compression-molded silicone products, we have the in-house design, engineering, and manufacturing capabilities to bring your vision to life.

Explore Our Custom Plastic Parts and Components

Explore Our Capabilities:

- Extruded Plastic Sections

- Simple Small Injection Molded Parts

- Large Injection Molded Parts

- Plastic Extrusions

- Compression Molded Silicon Cup Lids (Many Colors Available)

- Plastic Mugs

- Cast Acrylic Lure Heads

- Plastic Coffee Cups

- PEEK Gear Components

- Fully Assembled Aluminum + PEEK Gears (Injection Molding, CNC Machining, and CNC Hobbing)

- Plastic Connector Casing

- Plastic Pipe Fittings

- Injection Molding

- Vacuum Forming

- PVC Sheet

- Bath Tubs (Vacuum Forming, Acrylic Sheet)

- Large Rotomolded Box

Why Choose SureSource for Your Plastic Parts Manufacturing?

Cost-Effective Manufacturing

Competitive pricing without compromising on the quality you need.

Comprehensive Solutions from Start to Finish

From design and prototyping to manufacturing and quality control, we've got it all covered.

Unmatched Precision and Reliability

High standards of precision and attention to detail in every part we produce.

Global Reach with Local Expertise

North American presence with teams on the ground in Asia for seamless production.

Tailored Solutions for Your Unique Needs

Custom manufacturing solutions designed to meet your specific product requirements.

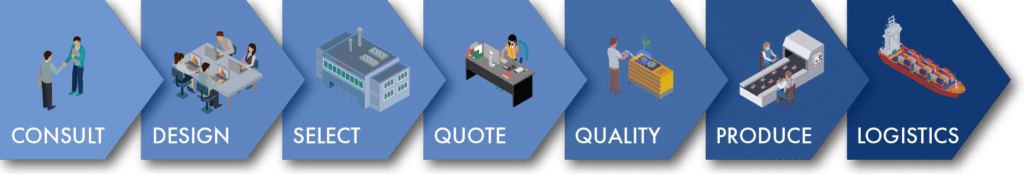

How We Bring Your Ideas to Life

At SureSource, we guide you through every stage of the plastic parts manufacturing process, starting with design and prototyping to ensure your product specifications are met. Our team then focuses on material selection and engineering, choosing the best techniques for cost-effective production.

In the production phase, we use techniques such as injection molding, rotomolding, and vacuum forming to produce high-quality plastic parts. Our quality control process guarantees that each product meets your exact specifications, followed by timely delivery to your location.

End-to-end manufacturing, from custom components to complete products, tailored for businesses.

Explore Our Full Range of Product Capabilities

Audio/Video

Speakers: headphones

Accessories

TV mounts

Stands

& More

Audio/Video Solutions

View MoreBattery Products

Prismatic

Pouch

Battery packs

Charging stations

& More

Battery Product Solutions

View MoreWood Products

Doors

Boxes

Painted

Vinyl

& More

Wood Product Solutions

View MorePackaging

Cardboard

Beauty boxes

Plastic hose

Recyclable

& More

Packaging Solutions

View MoreMetal Parts

Aluminum

CNC machined

Die castings

Gears

& More

Metal Parts

View MoreElectronics

PCBs

PCBAs

Semiconductors/ICs

Passive components

Power supplies

& More

Electronic Product Solutions

View MorePlastic Parts

Compression molded

Vacuum formed

Roto molded

Sheet

& More

Plastic Part Solutions

View MoreEV Motor & Vehicle Parts

Reduction Gearboxes

Batteries

Power electronics

Charging systems

& More

EV Motor & Vehicle Part Solutions

View MoreGreen Energy Products

Inverters

Turnkey systems

Fixed/portable

Home/industrial

& More

Green Energy Product Solutions

View MoreWires, Cables & Harnesses

HDMI

Speaker

Automotive

High voltage

& More